Top 6 Ways to Master Efficiency with Manufacturing Automation Solutions

It’s no secret that mastering efficiency is the key to staying ahead in the competitive realm of manufacturing. As technology continues to advance, embracing manufacturing automation solutions has become imperative for companies aiming to optimize their operations. Manufacturing automation plays a pivotal role in modern industrial processes, driving advancements in efficiency, precision, and innovation across a wide range of industries.

What is Manufacturing Automation?

Manufacturing automation refers to the use of various control systems for operating equipment in factories, warehouses, and other facilities, without direct human involvement in the production process. The primary objective of manufacturing automation is to improve efficiency, productivity, and quality in the manufacturing and production of goods.

The adoption rate of automated solutions within the manufacturing industry is also on the rise. Markets and Markets reports that the global industrial automation market size was valued at $147.9 billion in 2022 and is projected to reach $218.8 billion by 2027, growing at a CAGR of 8.2%. The significant growth in the manufacturing automation market indicates that organizations are acknowledging the advantages of automated solutions within their operations.

Key Components of Manufacturing Automation Solutions

From specialized machinery to the intelligence of control systems, the synergy delivered by advanced technologies in automated solutions continues to evolve and shape the future of production. Let's explore the key elements that define the seamless fusion of technology and manufacturing excellence.

Machinery and Equipment:

Automation involves the use of specialized machinery and equipment to perform tasks traditionally carried out by human operators. This machinery can range from simple conveyor belts and robotic arms to complex computer numerical control (CNC) machines and advanced robotic systems.

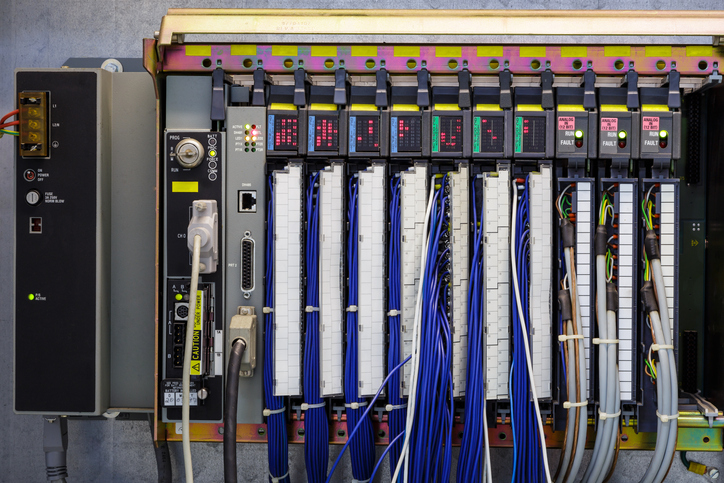

Control Systems:

Manufacturing automation relies on control systems to manage and regulate the operation of machinery. These systems use sensors, actuators, and feedback mechanisms to ensure precision, consistency, and responsiveness in the manufacturing process.

Sensors and Feedback Mechanisms:Sensors play a crucial role in automation by providing real-time feedback on various aspects of the production process. They can measure parameters such as temperature, pressure, position, and quality, allowing the control system to make instant adjustments for optimal performance.

Programmable Logic Controllers (PLCs) and Computers:

PLCs are specialized computers designed for controlling industrial processes. They are programmable and execute specific instructions to automate tasks. Computers, including sophisticated software systems, play a central role in designing, monitoring, and optimizing automated manufacturing processes.

Robotics:

Robotics is a key element of manufacturing automation, with smart robots performing tasks such as assembly, welding, painting, and material handling. The integration of robotic systems contributes to increased precision, speed, and flexibility in manufacturing operations.

Communication Networks:

Automation systems often rely on communication networks to facilitate data exchange between different components. This enables seamless coordination and synchronization of activities across the manufacturing environment.

Human-Machine Interface (HMI):

HMIs provide a means for human operators to interact with and monitor the automation system. These interfaces can include touchscreens, displays, and control panels, allowing operators to input commands, monitor processes, and troubleshoot issues.

.jpg)

.jpg)

Manufacturing automation offers several benefits, including:

- Increased Productivity. Automation can perform tasks at a faster pace and with greater accuracy than manual labor, leading to increased production efficiency.

- Cost Reduction. While the initial investment in automation technology can be substantial, it often results in long-term cost savings through reduced labor costs, minimized errors, and improved resource utilization.

- Enhanced Quality. Automation contributes to consistent product quality by eliminating variations that may occur with manual processes.

- Flexibility and Adaptability. Automated systems can be programmed and reprogrammed to handle various tasks and adapt to changes in production requirements.

Top 6 Ways Automated Systems Improve Efficiency in Manufacturing

1. Workflow Integration for Seamless Operations

The foundation of efficiency lies in the seamless integration of manufacturing automation into existing workflows. By connecting different stages of the production process, from design to delivery, companies can eliminate bottlenecks and enhance overall productivity.

2. Real-Time Data Analytics for Informed Decision-Making

Leverage the power of real-time data analytics to gain insights into every aspect of your manufacturing process. Monitoring key performance indicators allows for quick identification of areas for improvement, enabling agile decision-making and strategic adjustments to optimize efficiency.

3. Predictive Maintenance to Minimize Downtime

Unplanned downtime can significantly hamper production efficiency. Implementing predictive maintenance through automation solutions allows for the monitoring of equipment health in real-time, enabling proactive maintenance and minimizing disruptions to the production schedule.

4. Robotics for Precision and Speed

Incorporating robotics into manufacturing processes enhances precision and speed, two critical factors for efficiency. Robots can handle repetitive tasks with consistent accuracy, freeing up human resources for more complex and value-added activities.

5. Supply Chain Visibility for Enhanced Planning

Achieving efficiency extends beyond the production floor to the entire supply chain. Automation solutions can provide end-to-end visibility, enabling better planning, reduced lead times, and improved coordination with suppliers, resulting in a more streamlined and responsive production process.

6. Customization and Scalability for Adaptability

Embrace manufacturing automation solutions that offer customization and scalability. This adaptability ensures that the system can evolve with changing production needs, accommodating growth and technological advancements without significant disruptions.

Conclusion

The top six ways to improve efficiency with manufacturing automation solutions are a guide for companies wanting to make big changes. Strategically implementing automated solutions paves the journey toward mastering operational efficiency. From seamless workflow integration to the power of real-time data analytics and the precision of robotics, each strategy contributes to a holistic approach that culminates in operational excellence.

Want to remain at the forefront of innovation? You can receive the industry’s latest trends, insights, and updates by subscribing to our newsletter. Join our community of forward-thinkers and stay informed on the future of efficiency, precision, and innovation! Subscribe to The Current today!